Testing according to RTCA DO-227B

Minimum Operational Performance Standards for Non‑Rechargeable Lithium Batteries in Aviation

RTCA DO‑227B is one of the key aviation standards governing the safe design, testing, and installation of non‑rechargeable lithium batteries. Developed by the Radio Technical Commission for Aeronautics (RTCA), it serves as a binding technical foundation for manufacturers, integrators, and certification authorities worldwide. The most recent edition was released on December 12, 2024, and represents a fully updated version of DO‑227A.

- Background and Importance of the Standard

Non‑rechargeable lithium batteries (also known as primary lithium batteries) are used across a wide range of safety‑critical aircraft systems, including:

- Emergency Locator Transmitters (ELTs)

- Back‑up and standby power systems

- Navigation and communication equipment

- Monitoring and safety‑related instruments

Their high energy density makes them reliable but also potentially hazardous if design, quality, or thermal behavior are not strictly controlled. DO‑227B therefore defines Minimum Operational Performance Standards (MOPS) that ensure safe operation under all aviation‑related conditions.

- Scope of DO‑227B

The standard applies to:

- Non‑rechargeable lithium cells and batteries

- Battery systems, individually or as part of a larger assembly

- End items permanently installed on aircraft

Important:

Rechargeable batteries and portable electronic devices (PEDs) are not covered by DO‑227B.

- Objectives of the Standard

DO‑227B has three core objectives:

- Ensuring airworthiness of batteries under all operational and environmental conditions

- Defining test procedures to prevent thermal, electrical, and mechanical hazards

- Providing guidance for design and installation to support certification processes

These requirements guarantee that batteries perform safely even under malfunction or extreme environmental conditions.

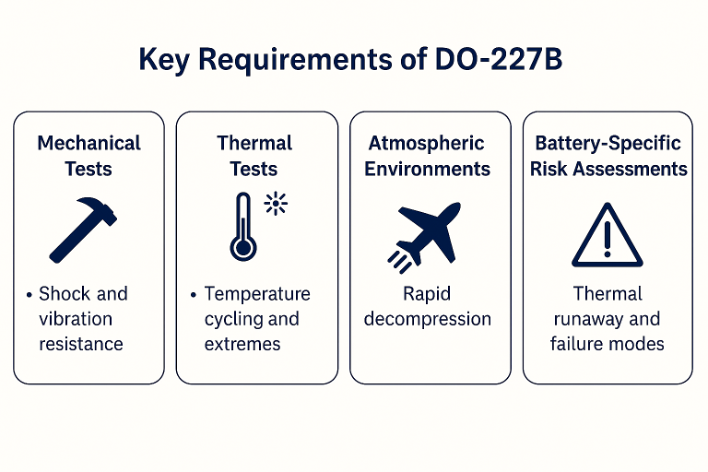

- Test and Evaluation Requirements

The standard contains a comprehensive matrix of tests, including:

4.1 Mechanical Tests

- Shock and vibration resistance

- Drop test

4.2 Thermal Tests

- Thermal shock / Temperature cycling

- High‑ and low‑temperature tests

4.3 Atmospheric Conditions / Altidue testing

- Rapid decompression

- Low‑pressure testing

4.4 Environmental Conditions

- Humidity and condensation testing

4.5 Battery‑Specific Safety Tests

- Assessment of thermal runaway

- External Short‑circuit and failure mode analyses

- Discharge current test

- Cell Venting Temperature Limit / Polarity reversal test

These tests ensure safe battery performance during normal and abnormal operational scenarios.

- Responsibilities of Manufacturers and Integrators

DO‑227B highlights the responsibility of those installing batteries in aircraft:

- Batteries must be proven fit for the intended operational environment

- Certification documentation must be complete and traceable

- End items containing more than one battery require additional evaluation

The standard emphasizes that not only the battery itself but also its integration into the aircraft system is safety‑critical.

- Key Updates Compared to DO‑227A

DO‑227B introduces significant enhancements:

- Updated insights into thermal runaway mechanisms

- More precise shock and vibration requirements

- Better‑defined test sequences and acceptance criteria

- Enhanced installation and safety requirements

These updates reflect technological advancements and operational experience while aligning with international standards such as EUROCAE ED‑62B.

- Importance for the Aviation Industry

DO‑227B plays a crucial role in modern aviation safety by:

- Reducing fire, leakage, and malfunction risks

- Helping manufacturers prevent design‑related hazards early

- Supporting regulators with standardized evaluation criteria

- Enabling operators to reduce operational risk and improve reliability

As primary lithium batteries continue to proliferate in avionics and emergency systems, the relevance of DO‑227B continues to grow.

Conclusion

RTCA DO‑227B represents the state of the art for the safe design and qualification of non‑rechargeable lithium batteries in aviation. Through comprehensive testing requirements, clear design guidelines, and structured documentation criteria, it provides a solid foundation for certification and safe operation under all aviation conditions.